News

What's a Freezing Point Depressant?

With over 15 years of experience our Engineering Director, Martin Herbert, was part of the research group at The University of Bristol who were responsible for developing the original Ice Pigging concept. Led by professor Joe Quarini, the inventor of Ice Pigging, Martin and his colleagues took the process of Ice Pigging out of the laboratory and turned it into the useful, practical industrial tool which we use today.

Now Martin gives us an insight into his role at Nivalis and some more in depth detail about how important the Freezing Point Depressant and additives are in the Ice Pigging process...

Share:

Posted on: 21st Mar 2024

What is your role at Nivalis?

I lead engineering at Nivalis. My role involves ensuring Nivalis deliver on both equipment and service offerings. This covers specifying equipment, surveying and planning service work, procurement, design, system assembly, onsite delivery training and after sales support.

What does a typical day at Nivalis involve for you?

The great thing about Nivalis is that there is no such thing as a typical day. One week I might be working with the team onsite in a toothpaste factory or onboard an aircraft carrier, another week I might be procuring various components for our next system build while producing an operator instruction manual. The next week I might be working in our technical centre testing how well Ice Pigging works in a pilot rig with a customer product or commissioning and signing off new equipment.

The team at Nivalis have been working on Ice Pigging from its inception so have extensive experience. Ice Pigging is elegantly simple as a concept but getting it to work effectively and reliably does require a really good understanding of the ice, equipment and also the customer’s process. At Nivalis we pride ourselves on taking the time to properly understand the customer's process and how Ice Pigging can be best applied.

What’s your background?

My whole career has been based around Ice Pigging so Nivalis is the obvious place to work. After graduating with a degree in Mechanical Engineering from Bristol University I joined the research group at the University that was pioneering Ice Pigging Technology. I worked with the group for 3 years while completing my PhD which examined the thermal stresses on water pipelines exerted during Ice Pigging. Since then I have been working on developing Ice Pigging equipment and applications.

What is the Freezing Point Depressant and why is it important in Ice Pigging?

We are all familiar with the ice cubes that come out of our freezer at home, they are large solid lumps that do not look like they would flow through a pipe. We are also familiar with the slushy drinks sold in theme parks and convivence shops, these are much more like the ice we use for Ice Pigging.

The clever bit that turns ice from a solid lump into a flowable slush is the Freezing Point Depressant or FPD for short. In the case of the slush puppy, the FPD is the sugar and citric acid which is added to the ice. As well as making children crave the drink, adding these ingredients disrupts the freezing process, dropping the temperature at which water freezes and creating a carrier liquid in which the ice crystals are suspended and which also reduces the tendency of crystals to stick together and form a solid lump.

In Ice Pigging we exploit this effect, along with the ratio of solid ice crystals to carrier liquid, to create a flowable Ice Pig. We tailor the additive type, concentration and ratio of ice and liquid to the specific application to maximise cleaning or product recovery, but minimise the energy required to make and store the ice and the chance of it being so thick it gets stuck in the line.

Which additives are used for Ice Pigging?

Anything that mixes or dissolves with the water will act as an FPD additive. Common examples include salt (table salt NaCl), sugar, critic acid, caustic soda and sodium sulphate.

The selection criteria for additives includes compatibility with the particular process or product (the best case is that the FPD is already an ingredient in the process or product being Ice Pigged), safety hazards related to both people and equipment, cost, availability on site, ease of mixing and how well it actually works to make an Ice Pig.

For each Ice Pigging job we will look at the pros and cons related to each criterion for a range of FPDs with the customer to decide on the right choice. For example, sodium hydroxide may be compatible with a process and work well for cleaning but is more hazardous so is only used if the right safety precautions can be practically applied. Salt is cheap and not hazardous to humans (unless you eat too much) but it can cause corrosion in some systems or can react with some materials to make them harder to clean. Sugar makes really good ice and is a very common ingredient, but you have to consider the sanitation requirements and shelf life carefully as it is as popular with bacteria as it is with humans.

There have been a number of occasions where we have had to research and test new FPDs to adapt to a customer’s process. Sodium sulphate was first used in the cosmetics industry as it is an ingredient in various products, it is also used in the feed water for a nuclear reactor steam turbine so when tasked with this application we already knew the right concentration. When we first worked with pharmaceutical customers they were keen to use caustic soda which was then used in the paint industry too.

The NIV500 Ice Pigging system has been specially engineered to deal with different FPDs by specifically having all stainless steel metallic components and being a closed system which mitigates the risks related to hazardous FPDs.

And finally, what's one of the odder jobs you do at Nivalis?

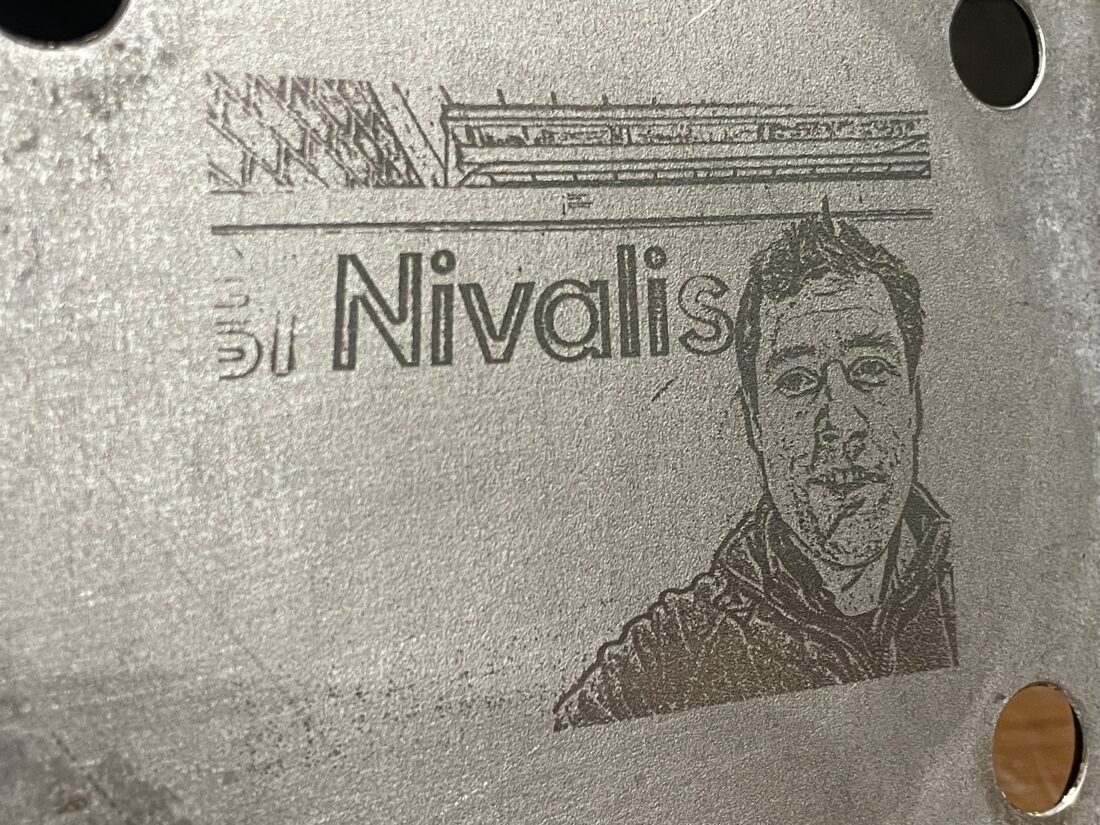

One of the strange roles I have at Nivalis is designing all of our decals, signage and marking. As well as having three different types of sticker machine we have also recently invested in a laser engraving machine. Over the years we have come up with some interesting and unique signage to instruct and inform operators!

I have also had to work on translating signage into German, French, Spanish, Japanese, Estonian and, hardest of all, Hebrew which was a particular challenge with text running from right to left!

To read more about Freezing Point Depressants click here. Or if you would like to speak to one of our team please get in touch here.